Why Choose Non-Destructive Testing Services?

February 11, 2022

Non-destructive testing services are an integral part of many different industries. Non-destructive testing, also known as non-destructive examination, is essential for the livelihood of businesses that rely on regular inspections to ensure that equipment is safe and productive. If you want to know more about why non-destructive testing is so essential, consider the following guide that will help you learn more about why this testing technique is important.

Non-Destructive Testing

First: what is non-destructive testing? Non-destructive testing techniques are examination / testing techniques which are designed to not be disruptive to the operation of equipment and assets. Non-destructive testing is essentially meant to allow companies the ability to avoid shutting down equipment for inspections. This has several benefits, which will be explored in the next section.

There are many different types of non-destructive testing techniques. These techniques include, but are not limited to:

- Visual inspections, or inspections which seek to find visual flaws or issues

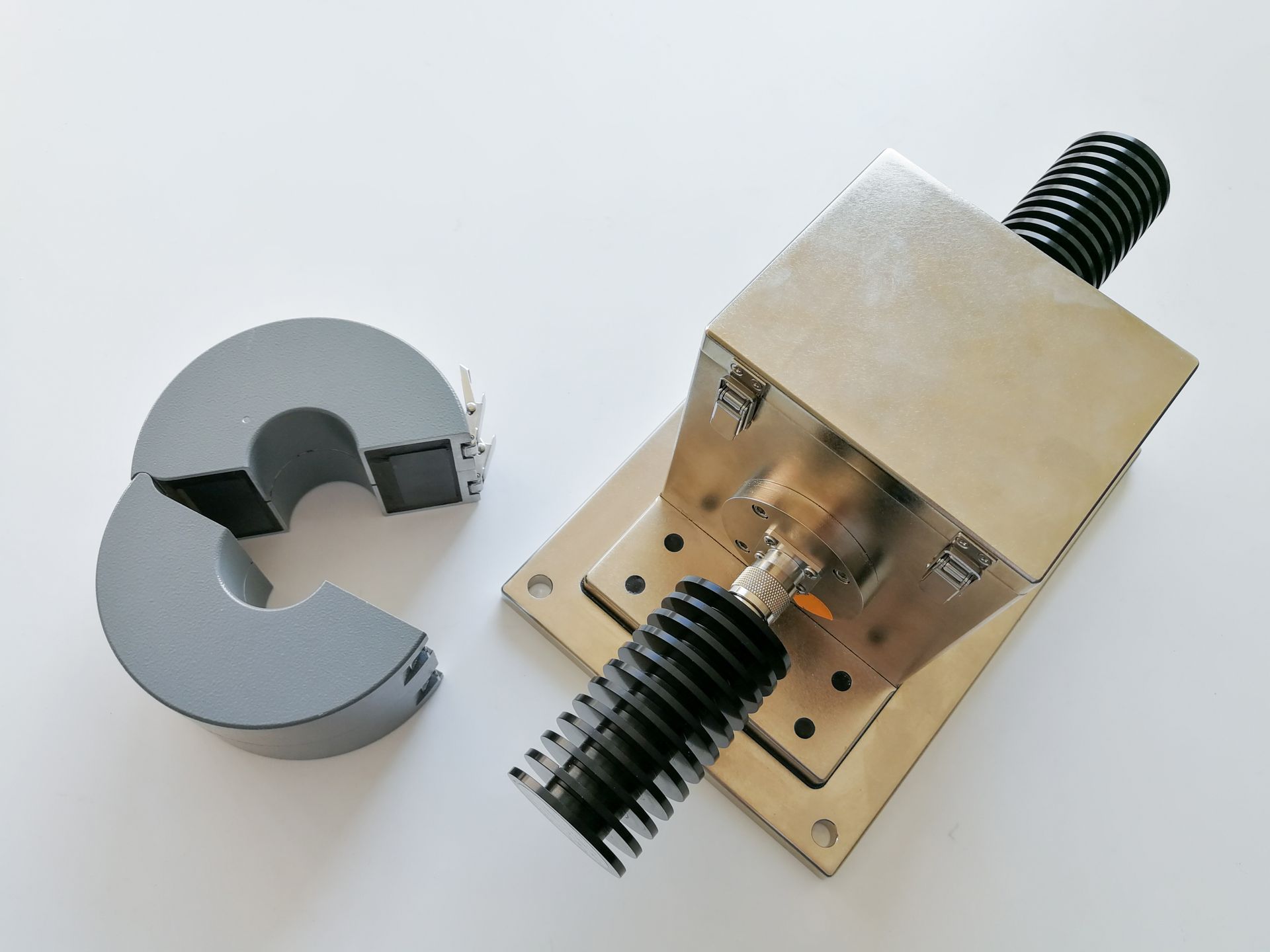

- Ultrasonic testing, or testing which uses ultrasonic waves to find issues and determine material characteristics

- Penetrant testing, or testing which uses penetrants to find leaks, cracks and similar issues

- Magnetic particle testing, or testing which uses magnetized material to find issues in iron, nickel and other magnetic materials

Benefits of Non-Destructive Testing and Why It’s Used

There are many benefits to using non-destructive testing, along with many reasons why companies choose this type of testing over others. Let’s take a closer look at these benefits and why they are beneficial to various industries.

Non-Destructive Testing is Non-Disruptive

Many types of equipment and asset testing are disruptive to the production process. They require equipment to be shut down entirely, because the equipment must be explored physically, whether that involves a testing technician entering equipment or taking it apart to search for potential issues.

Non-destructive testing, on the other hand, does not require equipment to be shut down. It can be safely done without disrupting the production.

This benefit is twofold: it allows for the productivity of the equipment to continue, which will not impact the output of the industry; this, in turn, allows for increased profits and decreased profit loss that would otherwise occur with a more disrupted examination.

Non-Destructive Examination Techniques are Tailored to the Equipment

While visual inspections are generally universal, the other types of non-destructive testing techniques are specifically tailored to different types of equipment. For instance, magnetic particle testing is designed for equipment that uses magnetic materials like iron and cobalt.

This specialization allows for a much more effective method of testing, as the techniques are more likely to detect flaws or potential issues when compared to generic disruptive forms of testing. In turn, this means that issues are much more likely to be spotted and fixed before they become more serious. This is not only beneficial because it avoids shut-downs due to equipment breaking down unexpectedly, but it’s beneficial for safety reasons as well.

If you aren’t certain which type of non-destructive testing is best for your industry, reach out to

Steel City NDT, as we’ll be able to help determine which testing is best for your needs.