How Winter Can Affect Your Pipeline Integrity and How NDT Helps

January 22, 2025

Winter can be a challenging time for maintaining the integrity of pipelines, especially in regions that experience extreme cold temperatures. The harsh winter weather conditions can lead to a variety of issues, such as pipe leaks, corrosion, and other structural damages. Understanding how winter affects pipeline integrity and how

non-destructive testing (NDT) can help is crucial for ensuring the safety and efficiency of pipeline operations.

Photo By: Matcor

The Impact of Winter on Pipeline Integrity

Pipe Leak Detection in Cold Conditions

Cold temperatures can cause materials to become brittle and more susceptible to cracking. When pipelines are exposed to freezing temperatures, there's an increased risk of leaks due to the expansion and contraction of metal components. Ice formation within pipelines can also lead to blockages and pressure build-up, which may result in leaks or bursts.

Pipe leak detection becomes even more critical during winter. It's essential to have a robust monitoring system in place to quickly identify and address any leaks before they escalate into more significant problems.

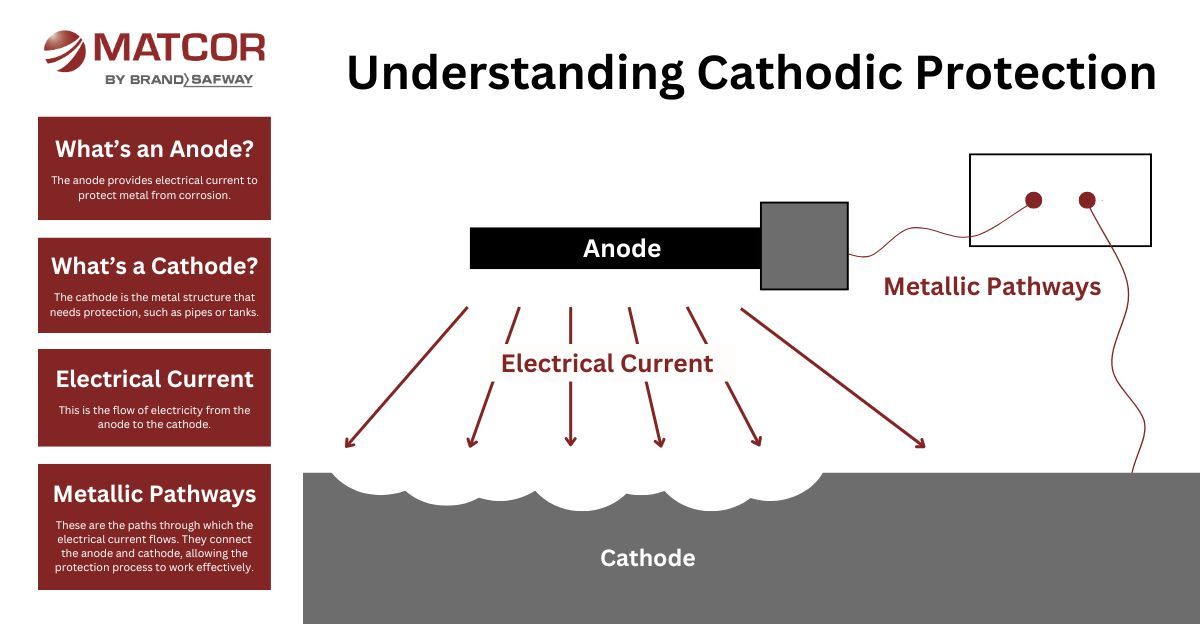

Effects of Cathodic Corrosion

Cathodic corrosion is another concern during winter months. Moisture from snow and ice can contribute to the electrochemical reactions that cause corrosion. When temperatures drop, the rate of corrosion can increase, compromising the structural integrity of the pipeline. Implementing cathodic protection systems is vital to prevent corrosion and extend the lifespan of pipelines.

The Role of Corrosion Monitoring

Corrosion monitoring is a proactive approach to managing pipeline integrity. It involves regular inspections and the use of advanced technologies to detect early signs of corrosion. By monitoring corrosion levels, companies can take preventive measures to address any issues before they result in costly repairs or environmental damage.

How Non-Destructive Testing (NDT) Supports Pipeline Integrity

Understanding Non-Destructive Testing

Non-destructive testing (NDT) refers to a range of techniques used to evaluate the properties of materials and structures without causing any damage. NDT is particularly valuable in the pipeline industry because it allows for the inspection and assessment of pipelines without interrupting their operation.

Key NDT Techniques for Pipeline Inspection

Several NDT techniques are commonly used in the pipeline industry to ensure the integrity of pipelines, especially during winter:

- Ultrasonic Testing (UT): This method uses high-frequency sound waves to detect flaws in materials. UT is effective in identifying cracks, corrosion, and other defects in pipelines.

- Magnetic Particle Testing (MPT): MPT is used to detect surface and near-surface defects in ferromagnetic materials. It involves applying magnetic particles to the surface of the pipeline and observing any patterns that may indicate defects.

- Radiographic Testing (RT): RT involves the use of X-rays or gamma rays to create images of the internal structure of pipelines. This technique is useful for detecting internal defects, such as corrosion and weld defects.

- Eddy Current Testing (ECT): ECT uses electromagnetic induction to detect surface and near-surface defects in conductive materials. It is particularly useful for detecting corrosion and cracking in pipelines.

The Importance of NDT Certification

NDT certification is essential for ensuring that testing is conducted accurately and safely. Certified NDT technicians have the skills and knowledge required to perform inspections effectively and interpret the results accurately. This certification ensures that pipelines are evaluated to the highest standards, reducing the risk of undetected defects.

Benefits of NDT for Winter Pipeline Integrity

Non-destructive testing offers several benefits for maintaining pipeline integrity during winter:

- Early Detection of Defects: NDT allows for the early detection of defects, enabling companies to address issues before they lead to significant damage or failures.

- Cost-Effective Maintenance: By identifying potential problems early, NDT can help reduce maintenance costs by preventing costly repairs and minimizing downtime.

- Enhanced Safety: Regular NDT inspections ensure that pipelines remain safe and operational, reducing the risk of accidents and environmental hazards.

- Compliance with Regulations: NDT helps companies comply with industry regulations and standards, ensuring that pipelines are maintained to the highest levels of safety and integrity.

Photo By: TWI

Strategies for Maintaining Pipeline Integrity in Winter

To ensure pipeline integrity during winter, companies should implement a comprehensive strategy that includes:

- Regular Inspections: Schedule regular inspections using NDT techniques to monitor the condition of pipelines and detect any signs of wear or damage.

- Implementing Cathodic Protection: Use cathodic protection systems to prevent corrosion and extend the lifespan of pipelines.

- Corrosion Monitoring: Continuously monitor corrosion levels and take preventive measures as needed to address any issues.

- Training and Certification: Ensure that all technicians conducting inspections are properly trained and certified in NDT techniques.

- Emergency Response Plans: Develop and implement emergency response plans to quickly address any pipeline leaks or failures that may occur during winter.

Conclusion

At Steel City NDT, we understand the unique challenges winter brings to pipeline integrity. The potential for pipe leaks and cathodic corrosion increases significantly during cold months. However, with proactive measures, you can safeguard your infrastructure effectively. Our non-destructive testing solutions are designed to provide early detection of defects, ensuring optimal pipeline performance throughout winter.

Investing in regular NDT inspections is crucial for maintaining safety and efficiency. We recommend integrating corrosion monitoring systems and ensuring that your team is trained and certified in the latest NDT techniques.

Don’t wait for problems to arise.

Contact Steel City NDT today to learn how our services can protect your pipelines from winter's harsh effects. Ensure your pipeline integrity and compliance with industry standards—reach out for a consultation or schedule an inspection with our certified technicians. Together, we can ensure the longevity and safety of your pipeline operations.

You might also like

NDT/NDE SERVICES

QUICK LINKS

CONTACT US

Steel City NDT, LLC

322 Mall Blvd. Suite 270 Monroeville, PA 15146

All Rights Reserved | Steel City NDT | Powered by Quantifi Media