How to Ensure Proper Preparation for Liquid Penetrant Inspections

November 15, 2024

Liquid penetrant inspections (LPI) are a crucial part of non-destructive testing (NDT). They help detect surface-breaking defects in various materials.

However, the accuracy of these inspections heavily relies on proper preparation. This involves several steps, from surface cleaning to the application of penetrant liquid.

This guide aims to provide a comprehensive overview of how to prepare for an LPI. It will cover everything from the basics of liquid penetrant testing to the importance of

NDT certification.

Whether you're a seasoned professional or a student seeking certification, this guide will equip you with the knowledge to ensure reliable and accurate LPI results.

Photo By: MagnaFlux

Understanding Liquid Penetrant Inspections

Liquid penetrant inspections are a simple yet effective method for detecting cracks and flaws. They are an integral part of the non-destructive testing process.

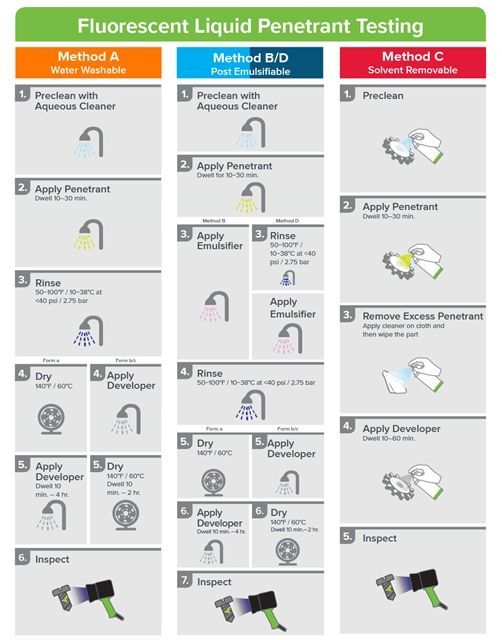

These inspections work by applying a

penetrant liquid to the part's surface. The liquid seeps into any cracks or defects, making them visible for identification.

Importance of Surface Cleanliness

Surface cleanliness is crucial for reliable liquid penetrant inspections. Contaminants can hide defects, leading to false results.

Oil, grease, and debris obstruct penetrant penetration. Clean surfaces ensure accurate defect visibility during inspection.

Step-by-Step Surface Preparation

Proper surface preparation is key to successful liquid penetrant inspections. The process involves meticulous steps to reveal defects clearly.

First,

clean the surface thoroughly. Use solvents or degreasers to remove contaminants like oil, dirt, and paint.

After cleaning,

dry the part completely. Moisture can dilute the penetrant, affecting inspection results.

Next,

apply the penetrant liquid evenly. Ensure complete coverage to allow the penetrant to seep into cracks.

Observe the dwell time, which is crucial. This allows the penetrant to saturate any defects, making them visible.

Finally,

remove excess penetrant without disturbing penetrated material. Use a clean wipe for this task.

Choosing the Right Penetrant Liquid

Selecting the appropriate penetrant liquid is vital for accurate liquid penetrant inspections. Consider the inspection environment and defect type.

Fluorescent penetrants provide high sensitivity and are ideal for dim conditions. Visible penetrants work well for general inspections, offering ease with natural light.

The Role of Developer in Enhancing Defect Visibility

The developer is crucial in making defects stand out during inspections. It draws penetrant liquid from defects, creating visible indications.

Different types of developers exist, like dry powder and wet non-aqueous. Each type enhances visibility, enabling more accurate interpretation of surface defects.

Photo By: MagnaFlux

Safety Precautions and Handling

Proper safety procedures are essential when handling penetrant liquids. Always wear appropriate protective gear, like gloves and goggles, to prevent skin and eye contact.

Use proper ventilation to minimize the inhalation of fumes. Follow

manufacturer's guidelines to ensure safe and effective handling of all inspection materials.

Interpreting Results and Documentation

Interpreting LPI results requires a keen eye and practice. Differentiate between true and false indications to prevent errors.

Document findings meticulously for quality control. Proper records ensure traceability and aid in historical analysis for maintenance and audits.

Conclusion: The Value of Proper Preparation

At Steel City NDT, we understand that proper preparation for liquid penetrant inspections is paramount to achieving accurate and reliable results. Our commitment to meticulous preparation enhances defect detection, ensuring the structural integrity and safety of the materials we inspect.

By adhering to best practices in liquid penetrant testing, we not only meet industry standards but also uphold the highest quality assurance measures for our clients. We invite you to partner with Steel City NDT for all your non-destructive testing needs.

Contact us today to learn more about how our expertise can help you maintain the safety and reliability of your operations. Together, we can ensure that every inspection counts.

You might also like