What is the Difference Between NDE and NDT?

October 11, 2024

In the world of engineering and manufacturing, the terms NDE and NDT are often used interchangeably.

However, these two acronyms represent distinct concepts within the realm of non-destructive evaluation. Understanding the difference between Non-Destructive Examination (NDE) and Non-Destructive Testing (NDT) is crucial for professionals in the industry.

This article aims to clarify these differences and shed light on the various methods and applications of each. Whether you're an NDT technician, a hiring manager for non-destructive jobs, or a company seeking NDT inspection services, this guide will provide valuable insights.

Let's delve into the fascinating world of NDE and NDT and explore their unique roles in ensuring the safety and integrity of materials and structures.

Understanding NDE and NDT

Non-Destructive Examination (NDE) is a broad term that encompasses all forms of non-destructive evaluation. It involves assessing the integrity of materials, components, or structures without causing damage.

Non-Destructive Testing (NDT), on the other hand, is a subset of NDE. It focuses specifically on testing and analysis. NDT methods, such as radiographic testing and penetrant inspection, are used to detect flaws and irregularities.

Both NDE and NDT play a crucial role in ensuring the safety and longevity of various products and structures.

They are widely used in industries like aerospace, automotive, construction, and energy.

Key Differences Between NDE and NDT

While both NDE and NDT are used to evaluate the integrity of materials without causing damage, they are not the same.

NDE is a broader term that includes all non-destructive evaluation methods. It not only involves testing but also includes other techniques like inspection, measurement, and data interpretation.

NDT, however, is a specific type of non-destructive examination. It focuses solely on testing and analysis to detect flaws and irregularities.

The choice between NDE and NDT depends on the specific requirements of the task at hand.

Understanding these differences is crucial for professionals in the field.

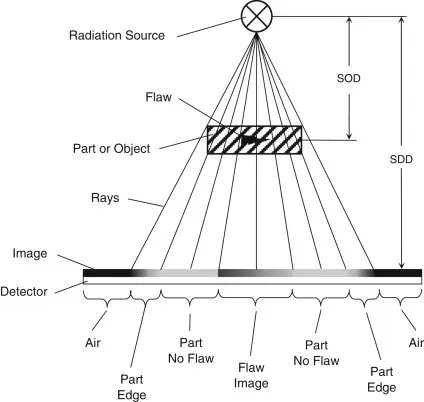

Photo By: Science Direct

Common NDT Methods and Their Applications

NDT encompasses a variety of methods, each with its unique applications.

Radiographic Testing (RT) is one such method. It uses X-rays or gamma rays to inspect the internal structure of a material. This method is particularly effective in detecting internal flaws that are not visible to the naked eye.

- Radiographic Testing (RT)

Another common NDT method is the Magnetic Inspection Test. It is used to detect surface and near-surface discontinuities in ferromagnetic materials. This method is often used in industries such as automotive and aerospace.

NDT Penetrant Inspection is another widely used technique. It involves applying a liquid penetrant to the surface of a material to reveal surface defects. This method is especially useful for detecting cracks and leaks.

Each of these methods has its strengths and limitations, making the choice of method dependent on the specific requirements of the inspection.

The Role of NDT Technicians and NDE Professionals

NDT technicians play a crucial role in the industry. They are responsible for conducting tests and interpreting the results to ensure the safety and integrity of materials and structures.

NDE professionals, on the other hand, have a broader scope. They not only conduct tests but also evaluate and analyze the data to provide comprehensive insights into the material's condition.

Both roles require a high level of skill and expertise, making them vital in industries where material integrity is paramount.

Importance of NDT Certification and Training

NDT certification is a testament to a technician's competence. It validates their knowledge and skills in conducting non-destructive tests, ensuring they can perform their duties effectively.

Training, on the other hand, equips technicians with the necessary skills. It covers various NDT methods, safety protocols, and data interpretation techniques.

Together, certification and training ensure that NDT technicians can deliver accurate and reliable results, contributing to the overall safety and quality of products and structures.

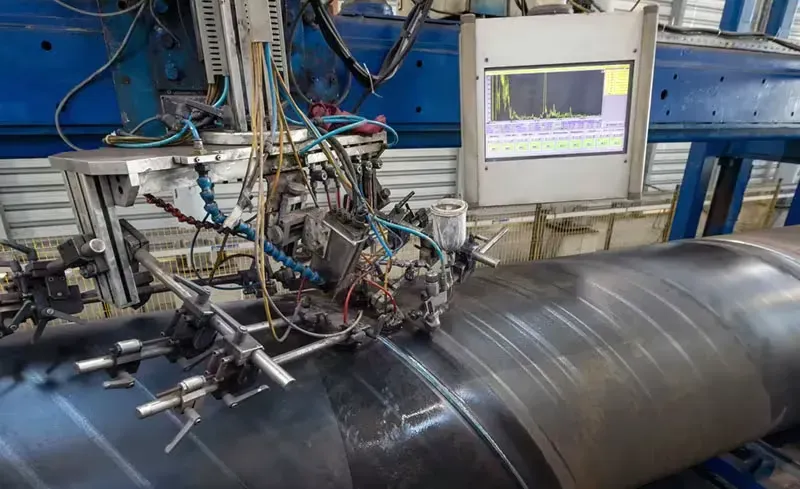

Photo By: Universal Technical Institute

Choosing the Right Method: NDE or NDT?

Choosing between NDE and NDT depends on the specific needs of the task. NDE is a broader approach, suitable for comprehensive evaluations of materials or structures.

NDT, being a subset of NDE, is more focused. It's ideal for specific testing needs, such as detecting surface or internal flaws.

The choice between NDE and NDT should be guided by the nature of the material, the type of potential defects, and the required level of detail in the analysis.

In essence, the right method ensures accurate results and optimal resource utilization.

Conclusion: The Impact of NDE and NDT in Industry

At Steel City NDT, we recognize the pivotal role that Non-Destructive Examination (NDE) and Non-Destructive Testing (NDT) play in ensuring the safety and integrity of materials and structures across various industries. Our commitment to employing the latest NDT methods, including radiographic testing, magnetic inspection tests, and penetrant inspection, allows us to deliver reliable and accurate results that contribute to product reliability and consumer safety.

These non-destructive inspection techniques also provide significant economic benefits. By facilitating preventative maintenance and stringent quality control, we help businesses reduce the risk of costly failures and ensure compliance with industry standards.

In conclusion, understanding the difference between NDE and NDT is essential for their effective application in any industry. If you’re looking for expert NDT inspection services or need assistance with NDT certification and training,

contact us at Steel City NDT to ensure the optimal safety and integrity of your materials and structures.

You might also like